Don’t change the system fix the flaw

Imagine the

annual increase...

140 mil. tons

Roughly a mass of

14 000 Eiffel towers go

to landfills yearly

27 mil. tons

Roughly a mass of

13 000 London Eyes are

burned yearly

1 Texas

That’s the size of the biggest

floating object in the pacific ocean

made of plastic

What if we brought them back

Product

ProductCollection of waste & material combination

The raw material, in the form of waste film, is procured from collection yards or directly from waste producers both within the Czech Republic and internationally.

Sorting & Cutting

After collection, quality inspection, and resizing, the next step involves additional sorting and cutting.

Seven-stage washing

A highly efficient 7-stage washing process with the purpose of eliminating all kinds of impurities from the waste material stream.

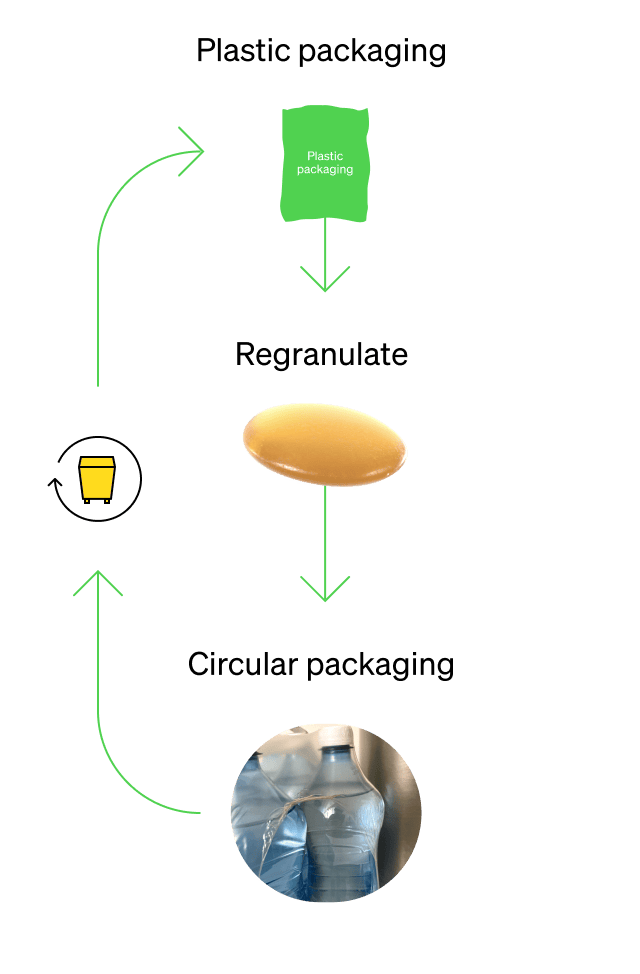

Process of regranulation

Similar to metal recycling, melting the material at high temperatures guarantees the removal of impurities

Homogenization

During this stage, the material is carefully blended to meet the specified batch parameters, guaranteeing optimal material stability.

Extensive quality checks

By conducting laboratory analyses on various grades, we determine the quality of individual batches in alignment with parameters specified by the client.

Top properties

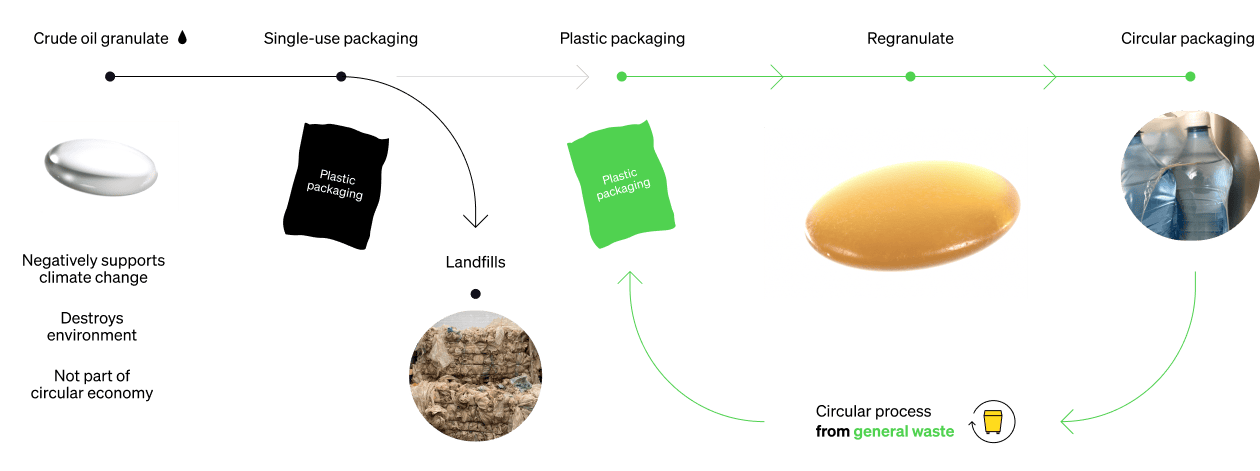

Empowering Change through up to 100% Crude Oil Substitution

We're offering an industry-changing regranulate that's paving a way for a more sustainable future.

Achieving up to +50% CO2 savings

Extras

Fosters Packaging Sustainability, Nurtures ESG Ambitions, and Ignites Circular-Economy Drive

Brings financial savings compared to crude oil commodity

You pay 0 in a form of plastic taxes

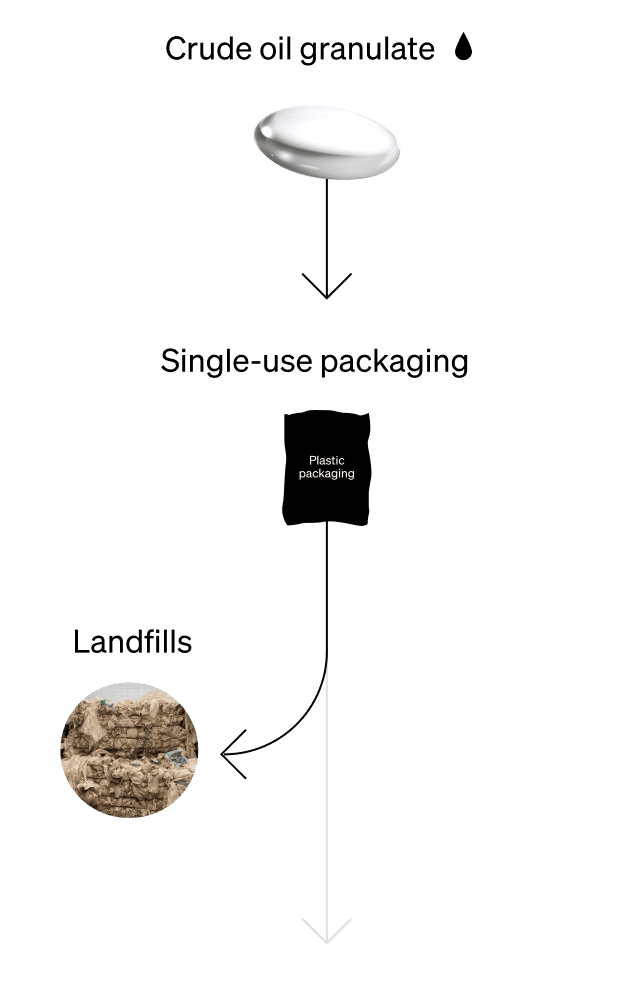

Traditional process

Our process

As time flies by, the demand to change the course of our planet strengthens.

UK begins 200£ / ton tax for plastics with less than 30% recycled content

Each non-recycled ton of plastic waste will be penalized. 800 EUR tax and repaid by member states.

2025-2030 deadlines for Landfill bans across the Europe - creates rapid increase of recycling capacity demand and carbon neutral policy.

We are able to help in all 3 spheres of the market!

How do we help Petrochemical industry

The petrochemical industry will utilize our material for dry-blending or compounding. Being the main source of plastic materials, this industry also functions as the most robust distribution channel in the market.

By incorporating our solution, businesses can seamlessly integrate recycled plastic, allowing them to maintain their existing sales portfolio while also tapping into new potential markets.

Through our solution, they transition from being problem "creators" to becoming proactive problem solvers.

Through our solution, they transition from being problem "creators" to becoming proactive problem solvers.

How do we help Manufacturing industry

The Manufacturing industry is dedicated to producing plastic packaging and other items, with oil serving as a dependable input for daily production.

Nevertheless, they encounter substantial pressure to prioritize sustainability.

By partnering with us, they gain not only a reliable production input but also a powerful tool for enhancing sustainability. Our top-quality materials guarantee optimal efficiency in their production processes and serve as a viable alternative to oil feedstock.

Through our collaboration, they can directly provide circular packaging solutions to end consumers.

Through our collaboration, they can directly provide circular packaging solutions to end consumers.

How do we help Brand owners

Brand owners prioritize distributing their own products, which are packaged to ensure safe transportation, maintain quality, and enhance safety.

They bear the responsibility for their product's packaging and its environmental implications, considering both end-user demand and the promotion of sustainable communities.

We assist them in reaching their sustainability objectives through engagement with B2C consumers.

We assist them in reaching their sustainability objectives through engagement with B2C consumers.

The most valuable

resource is action

resource is action